Unfortunately, Teflon coatings do not have an infinite life span, and over time these coating will wear and the benefits of the coating will diminish.

The rate of wear for a Teflon coating depends and many different factors, including the type of Teflon coating, the environment is is being used in, and the conditions it is subjected to.

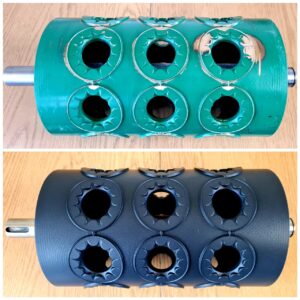

HOWEVER…. The good news is that whilst Australian Non-stick Coatings are specialists in the application of new Teflon coatings for a wide range of new items and equipment, we also specialise in the Stripping of old Teflon coatings and the Re-application of a new Teflon coating onto previously coated items.

Whilst the stripping and re-coating processes add between 10 – 30% to the cost compared to coating of new items, this extra cost more than out weighs the cost of replacing entire items. For most applications, the items can be stripped and re-coated multiple times, giving excellent cost savings, and reducing the cost of purchasing spare parts.

The most common items that Australian Non-stick Coatings re-coat are:

- Tray Sealing Plates and Sealing Bars/Jaws

- Food Processing and Packaging Equipment

- HDPE/PE Butt Welder Heater Plates

- Industrial Knives and Blades

- All Types of Moulds

- Ink and Glue Trays

- Pharmaceutical Processing Equipment

- Chemical Processing Equipment

For more information on our range of Teflon coatings and other services, to discuss how our coatings and services can assist your business and processes, or to receive a quote for the Teflon coating or re-coating of your items, please head to our CONTACT US page to select how you would like to contact us.

Teflon Re-coating

Our range of Teflon coatings includes PTFE, PFA, FEP and ETFE Teflons, including FDA approved Teflons for direct food contact applications.